Applications include proof of boiler flow air conditioning controlling of dampers according to flow and protecting pumps motors and other equipment against low or no flow.

Thermal air flow switch.

Media examples include nitrogen and scrubber exhaust fumes.

Fci flow switches feature thermal dispersion technology in which the temperature difference is greatest in a no flow condition and decreases as flow increases cooling the heated rtd.

The 1a relay provides a reliable switch interface with remote devices such as a plc scada or alarm.

Thermal flow switches are sensors with an electrical contact output at a specific flow rate.

Thermal air flow switches type sl.

The fst 320 series thermal dispersion flow switches especially designed for use with gases sense changes in the heat transfer characteristics of the gases.

Applications include chillers hot water heaters and liquid transfer systems.

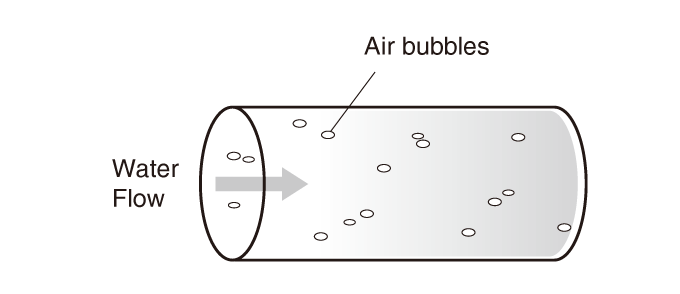

The thermal switches are based on convective heat transfer.

Dwyer models provide a complete system for leak detection and feature a selectable no or nc operation.

These switches or sensors can be used to monitor flow over a given period of time or set up to continuously monitor total flow.

The model t21 point flow switch uses a thermal differential technique to measure liquid or gas flow level or interface by sensing changes in the thermal heat transfer characteristics of the media where it is located.

Paddle flow switches or vane sensors with an electrical contact output are at a specific flow rate.

Thermo flotm thermal dispersion air flow switch.

Flow flow switches thermal.

Changes in flow velocity directly affect the extent to which heat dissipates and in turn the magnitude of the temperature difference between the rtds.

One sensor is at the process temperature and the other is being heated by a constant power.

Thermal dispersion flow switches for use with gases fst320 series.

A set point is established so when that specific temperature difference is reached the relay changes state.

The general purpose gas flow switch is a great choice for a broad range of relatively clean gases with non coating characteristics.

Flow sensors flow meters.

The sensor consists of a pair of matched resistance temperature detectors rtds encased in twin 316 series stainless steel tubes.

As the flow rate increases the temperature difference between the sensors decreases.

Commonly manufacturing facilities rely on flow sensors to.